Home / EV Charging News / The Environmental Impact of Electric Car Manufacturing: Analyzing the life cycle assessment of electric vehicles, including the carbon footprint and resource consumption associated with their production

Electric cars have gained significant attention as a sustainable transportation solution in recent years, primarily due to their lower carbon emissions compared to traditional combustion engine vehicles. However, it is essential to examine the environmental impact of electric car manufacturing to understand the complete sustainability picture. Through life cycle assessment (LCA), we can analyze the carbon footprint and resource consumption associated with the production of electric vehicles, shedding light on their overall environmental performance.

Life Cycle Assessment is a comprehensive methodology that evaluates the environmental impact of a product throughout its entire life cycle, from raw material extraction to disposal. It takes into account all stages, including manufacturing, transportation, use, and end-of-life treatment. LCA provides a holistic perspective on the environmental consequences of a product, helping policymakers and manufacturers identify areas for improvement.

The production of electric vehicles involves several key stages, each with specific environmental implications. Let’s explore these stages and their impact on the environment.

Electric vehicles heavily rely on certain materials, such as lithium-ion batteries and rare earth metals. However, the extraction and processing of these materials come with environmental concerns.

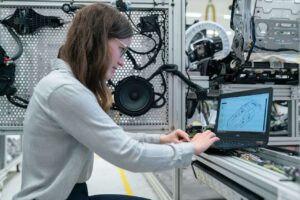

The manufacturing and assembly of electric vehicles involve various processes that contribute to their environmental impact.

The carbon footprint of electric car manufacturing encompasses greenhouse gas emissions generated throughout the production process.

The production of electric vehicles emits greenhouse gases through energy consumption, material extraction, and manufacturing processes. The main sources of emissions include the electricity used in manufacturing facilities, the extraction and processing of raw materials, and the manufacturing of components.

Although electric vehicles have a higher carbon footprint during the manufacturing phase compared to conventional vehicles, their operational phase significantly reduces overall emissions. Studies have shown that electric vehicles can offset their higher manufacturing emissions within a few years of use, resulting in lower lifetime emissions when compared to ICE vehicles.

In addition to carbon emissions, electric car manufacturing consumes various resources.

To address the environmental impact of electric car manufacturing, several strategies can be implemented.

While electric vehicles offer substantial environmental benefits during their operational phase, it is crucial to consider the environmental impact of their manufacturing process. Conducting life cycle assessments, reducing carbon emissions, and implementing sustainable practices throughout the supply chain are key to ensuring a greener and more sustainable electric vehicle industry. By striving for continuous improvement and innovation, we can further minimize the environmental footprint of electric car manufacturing and accelerate the transition to a sustainable transportation future.

$4,150.00 Original price was: $4,150.00.$3,990.00Current price is: $3,990.00.

$10,690.00 – $11,390.00

Your Power Management Partner for Over 25 Years Future Generations Depend on Our Decisions Today ™

2024 © All rights reserved by CyberSwitching